【Application Solution】 Isolated SPI Solution

In the evolution of Battery Management System (BMS) architecture, the choice of communication topology directly determines the system's reliability, cost, and scalability.

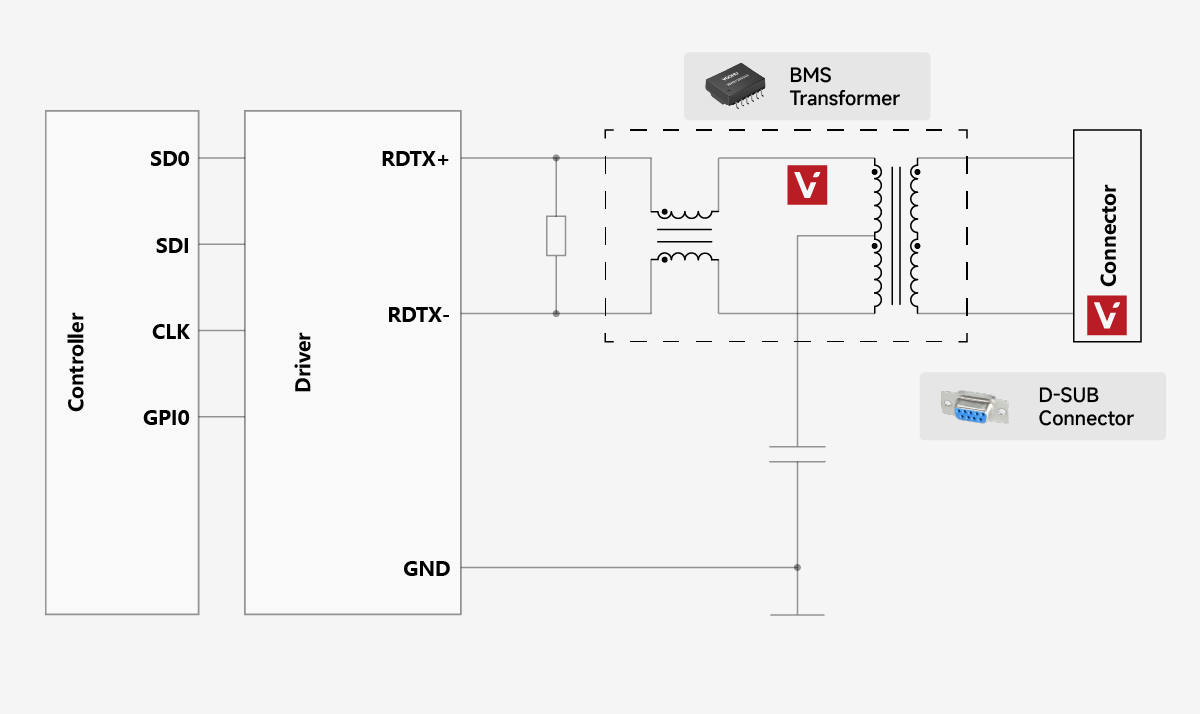

The mainstream isolated SPI solution builds a robust "protective wall" against interference through electrical isolation and differential signal transmission. Isolated SPI achieves electrical isolation via transformer or capacitor coupling, capable of withstanding voltage differences of hundreds or even thousands of volts.

In a BMS, the high-voltage and low-voltage side MCUs of the battery pack must be isolated. Traditional solutions require a 4-channel digital isolator, while isoSPI only requires a small transformer, significantly reducing costs. This isolation capability not only protects the low-voltage side processor from high-voltage surges but also greatly improves common-mode rejection, ensuring measurement accuracy.

In the modern wave of electrification, batteries have long transcended the traditional power unit, becoming the "heart" and "nerve center" of intelligent vehicles. However, every beat of this heart involves complex electrochemical reactions. Tiny differences among hundreds of battery cells during charge-discharge cycles can evolve into catastrophic thermal runaway or capacity decay. Ensuring that each cell operates both independently and collaboratively has become a core challenge in BMS system design. VOOHU Technology has been deeply involved in the automotive electronics field for over a decade, and has launched its SPI isolated communication solution.

1. Topology Introduction

VOOHU's SPI solution abandons the cumbersome wiring of traditional parallel buses, adopting an isolated SPI topology. Each SPI chip is precisely connected in series with adjacent boards, forming a "digital neural chain" from the battery cell module to the terminal BMU.

The ingenuity of this design lies in the fact that data is transmitted step-by-step on twisted-pair cables in differential signal form, with clock and chip select signals distributed synchronously. Each node is both an information acquisition terminal and a signal relay station.

Compared to the arbitration delay and broadcast storm risk of CAN bus, the deterministic communication timing of the daisy-chain topology ensures voltage and temperature sampling synchronization accuracy of <1μs. Compared to the point-to-point limitations of traditional SPI, VOOHU's isolated SPI solution extends the transmission distance to over 15 meters through isolation transformer coupling, supporting up to 16 cascaded levels, perfectly adapting to various battery pack physical layouts from 48V mild hybrid to 800V high-voltage platforms.

Ultimately, what converges to the BMU is not just discrete data points, but a complete battery health map—the SOH, SOC, and internal resistance trends of each cell are dynamically presented at the millisecond level, providing a panoramic input for battery balancing strategies and fault early warning.

2. Device Matrix Recommendation

VOOHU understands that the reliability of a BMS is determined by its weakest link.

Therefore, the solution provides a full-stack selection library from connectors to power devices, covering the entire development cycle from prototype to mass production:

Mechanical Interface: Scenario-Specific Matching of D-sub Connectors

For different battery pack installation spaces and vibration levels, three series of D-sub connectors are provided: 25P, 15P, and 9P.

The 25P version is suitable for high-voltage battery packs with 16 or more cells, integrating power, CLK, CS, and multiple differential signals; the 15P is designed for mid-range platforms with 8-12 cells, optimizing PIN utilization; and the 9P is designed for the minimalist design of micro power tools.

All connectors are USCAR-2 vibration level III certified, with gold-plated terminals ensuring a 500-cycle mating life, and IP67 protection against battery pack condensation corrosion.

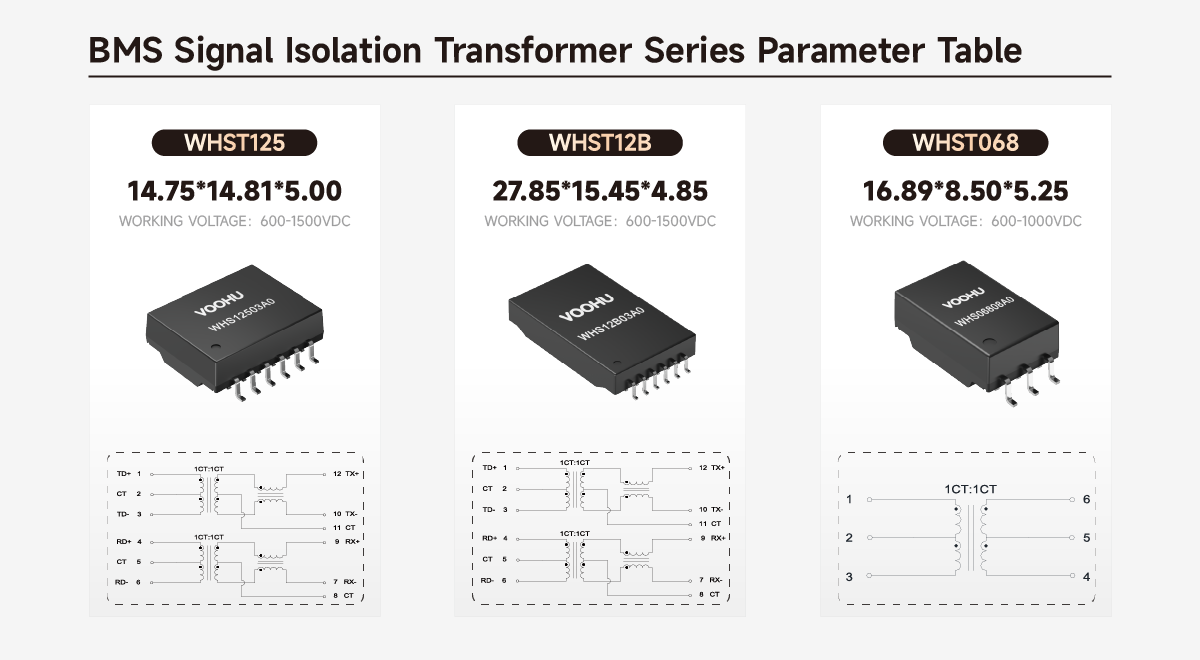

Isolation Core: Bms Isolation Transformer Series

As the "heart" of SPI electrical isolation, VOOHU offers three series: S12, S125, and S068.

The S12 series is suitable for operating voltages up to 250Vrms, with a withstand voltage rating of 3kV;

The S125 series is designed for 800V high-voltage platforms, employing a segmented winding design, with a withstand voltage up to 5kVrms;

The S068 series is customized for size-sensitive PHEV battery packs, with a height of only 3.5mm, yet maintaining ±2% coupling coefficient accuracy within an automotive-grade temperature range of -40℃ to 125℃, ensuring differential signal edge integrity.

Sampling Brain: Precise Protection of the AFE Chip

The AFE chip performs the dual functions of single-cell voltage/temperature sampling and emergency interruption protection.

The AFE in the VOOHU solution supports 16-channel synchronous sampling, with voltage accuracy ±1.5mV and temperature channel NTC accuracy ±0.5℃.

Key to its strength lies in its hardware overvoltage/undervoltage comparator, which can trigger a drive signal within <10μs, directly shutting down the MOSFET without MCU intervention, providing hardware-level safety redundancy for extreme scenarios such as thermal runaway.

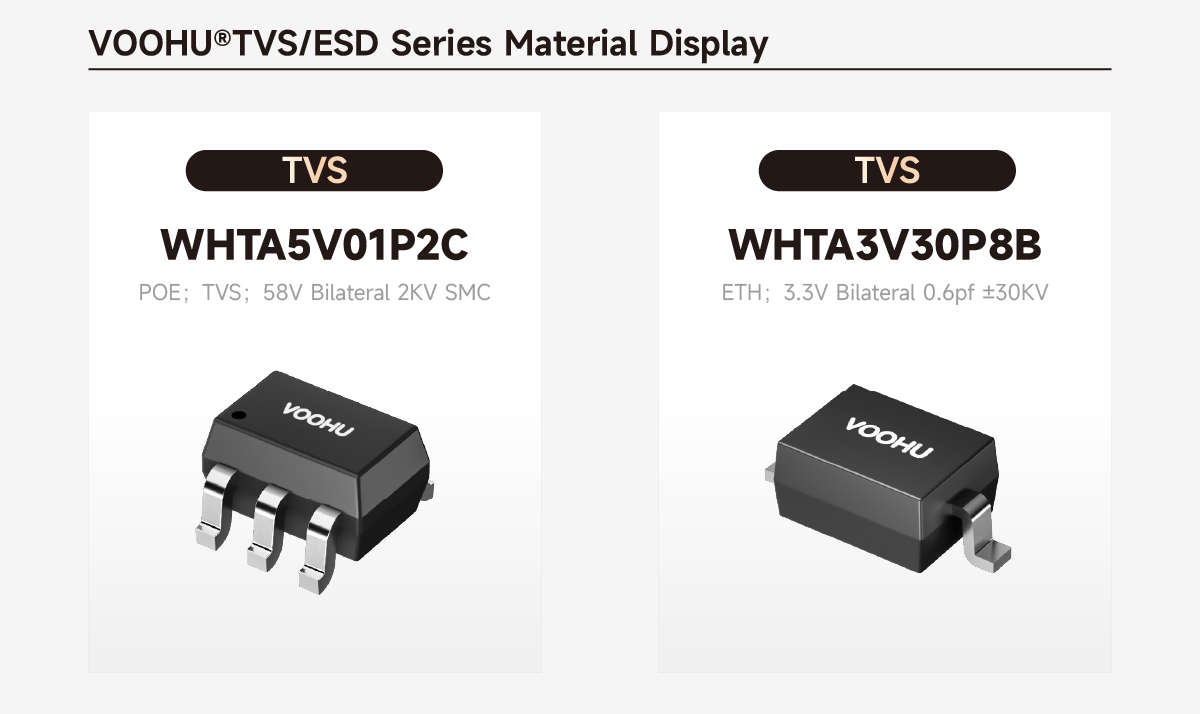

Protection and Execution: Collaborative Protection of TVS and MOSFETs

TVS Protection Device: A TVS array is deployed at the AFE input and SPI bus interface, with a clamping voltage <40V and a response time <1ps, effectively suppressing surges and ESD impacts caused by relay switching within the battery pack.

High-Voltage MOSFET: As the electronic switch in the main circuit of the battery pack, it undertakes the 400V/600A level switching task.

VOOHU prioritizes automotive-grade SiC MOSFETs, with an on-resistance <2mΩ and a 60% reduction in switching losses. Its drive signal comes directly from the hardware protection output of the AFE, ensuring the shortest fault response path.

The value of the VOOHU SPI solution extends beyond battery management.

3. Servo Motor Applications

In the field of servo motor control, the same architecture demonstrates remarkable applicability: The current sensor (analog AFE), encoder (digital SPI node), and driver (MOS transistor array) of a multi-axis motor are daisy-chained to the central controller. 80ns-level synchronous sampling ensures precise decoupling of the FOC algorithm. Isolation transformers block common-mode noise between power ground and control ground, and TVS protection resists EMI from IGBT switches.

This "from individual unit to system" design philosophy makes VOOHU's SPI solution a high-speed, accurate, and reliable neural transmission general-purpose architecture in electrification platforms. It helps customers use a single design toolchain to cover both the BMS and electric drive systems, significantly reducing supply chain complexity and certification costs.

From its founding in 2018 to its overseas expansion in 2025, VOOHU Electronics has become a reliable partner for over 1000 companies thanks to its "superior quality, reasonable prices, attentive service, and reliable delivery."

If you're also looking for a reliable, cost-effective, and hassle-free supplier of communication electronic components, consider VOOHU. After all, with over 100 listed companies as a partner, you can't go wrong.

Choosing VOOHU is truly reliable—it's not just a slogan, but the answer written with the trust of over 1000 customers over 8 years.

Newsletter subscription

Subscribe to our newsletter and stay updated on the latest information of our company and product.

Name

|

I agree that the information that I provide will be used in accordance with the terms of Voohu International Inc. Privacy & Cookies Policy