Locking in professional connectivity: VOOHU XLR RJ45 panel mount socket, designed for demanding environments.

Locking in professional connectivity: VOOHU XLR RJ45 panel mount socket, designed for demanding environments.

In the fields of professional audio, video transmission, and stage lighting control, a seemingly minor connectivity issue can bring a meticulously planned performance or important event to a standstill. Vibration, frequent plugging and unplugging, and complex electromagnetic environments constantly test the robustness and stability of network connections. The flimsy plastic clips of traditional RJ45 interfaces have become a potential bottleneck to system reliability.

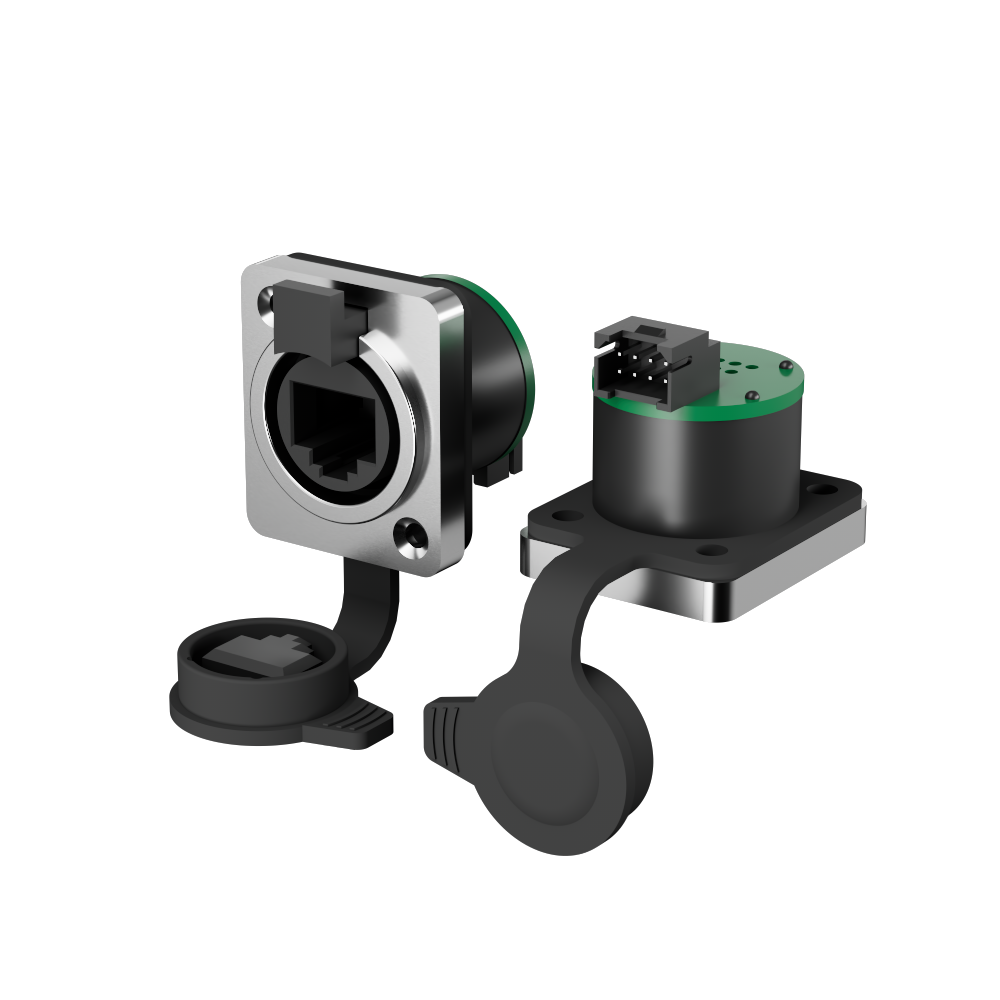

To address this, VOOHU has launched the XLR-style RJ45 panel mount socket (also known as the XLR A-series) designed specifically for high-standard applications. It innovatively integrates the classic XLR connector locking concept with the RJ45 network interface, aiming to provide a more robust, reliable, and professional physical layer solution for professional audiovisual and lighting networks.

1. Why are XLR RJ45 connectors needed?

In mobile performances, fixed installations, and high-interference environments, connectors must possess the following characteristics:

Vibration and anti-dislodgement: Mechanical latches ensure a secure plug lock, preventing signal interruption due to cable pulling or equipment movement.

High-efficiency shielding: The metal housing version effectively resists external electromagnetic interference, ensuring pure data signals.

Professional appearance and durability: Adaptable to professional equipment panels, durable, and enhancing the overall system quality.

The VOOHU XLR Ethernet series is designed to solve these core pain points.

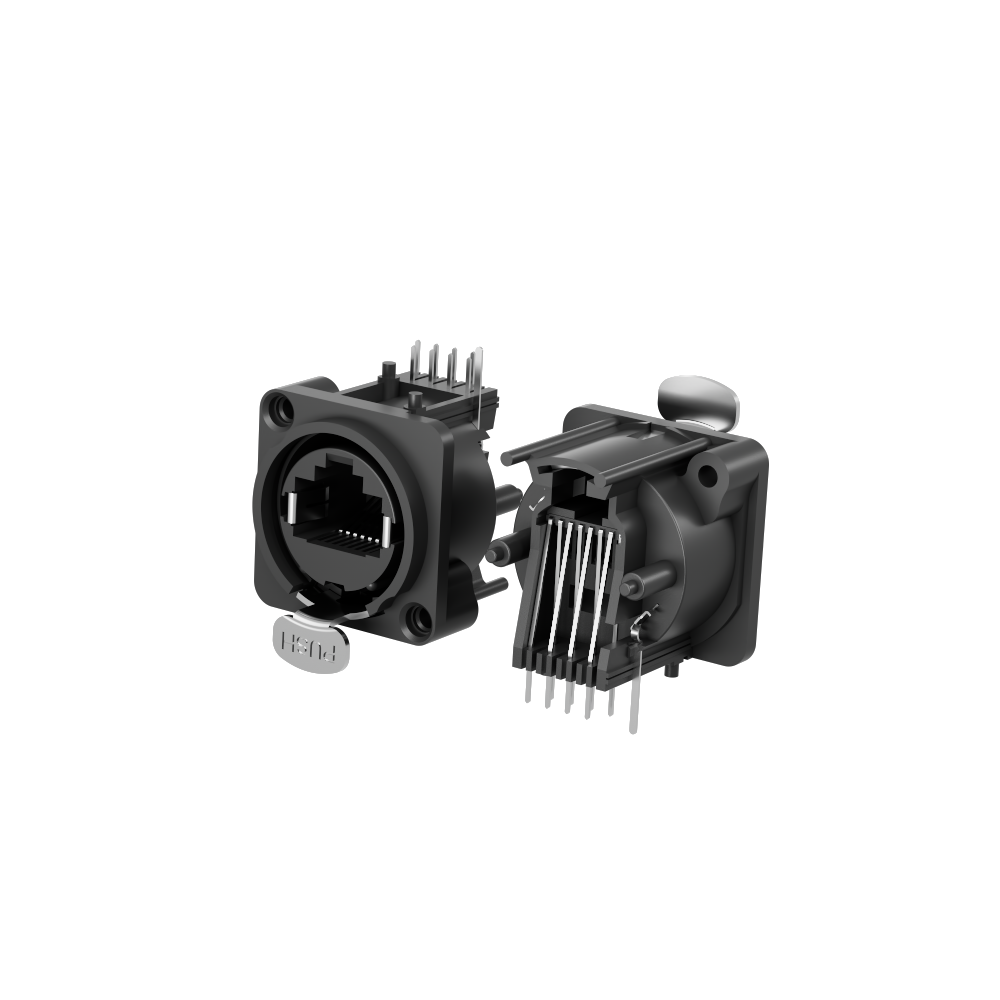

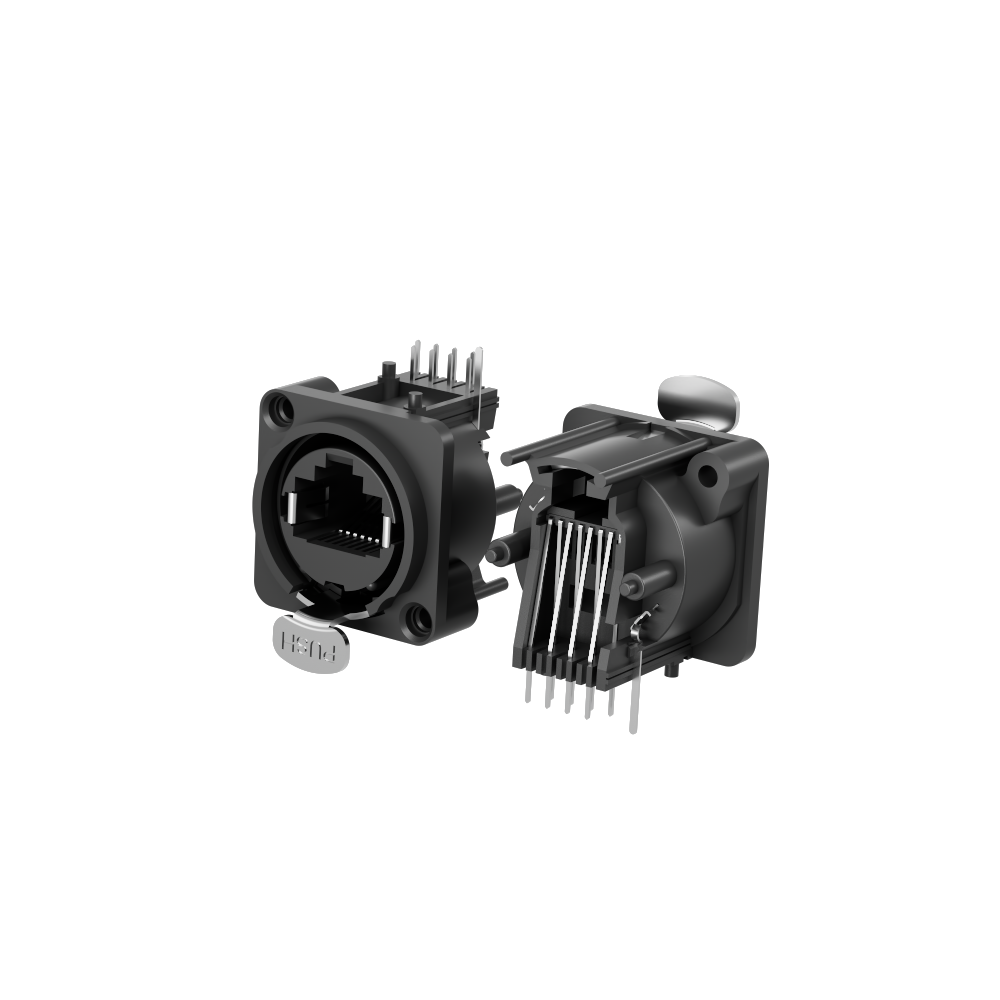

2. Two Options, Fully Adaptable

To meet the needs of different scenarios, we offer two material options:

All-plastic version: Economical and lightweight, cost-effective, suitable for internal rack interconnection and environments with low electromagnetic shielding requirements.

Metal panel version: Featuring a zinc alloy die-cast housing, it offers superior electromagnetic shielding (EMI/RFI) performance and a more industrial look, making it the preferred choice for demanding projects and high-end equipment.

3. Core Design: Stable Installation, Convenient Locking

Flexible Installation: Supports both vertical and horizontal PCB mounting orientations (90°/180° pins), perfectly adapting to different chassis internal layouts. Designed specifically for industry-standard panel openings.

Reliable Locking: The socket features a built-in stainless steel mechanical latch, forming a secure connection when mated with the matching XLR RJ45 male connector. Easy unlocking is achieved by pressing the "PUSH" button; operation is intuitive.

Wide Compatibility: Compatible with panel thicknesses up to 3mm, offering front/rear mounting options. Securely fastened with M3 screws for stable and convenient installation.

4. Detailed Technical Specifications

Rear Mounting

Electrical Performance

Contact Resistance: < 50mΩ

Insulation Resistance: > 0.5GΩ

Insulation Strength: 1kV DC

Transmission Performance: Fully compliant with CAT5e / Class D standards, supports TIA/EIA 568C and ISO/IEC 11801 channel specifications.

Power Support: PoE++ compatible (IEEE 802.3bt Type 4), maximum power handling 100W.

Important Note: Designed for CAT5e systems; do not use with CAT6/6A connectors.

Mechanical Properties and Environment

Insertion/Extraction Force: ≤ 20N

Insertion/Extraction Life: > 1000 cycles

Operating Temperature: -30°C to +80°C

Protection Rating: IP65 (Dustproof, Waterproof)

Flame Retardant Rating: UL94 V-0

Materials and Processes

Contacts: Phosphor Bronze, Gold Plated (1μ″)

Latch: Stainless Steel

Housing: PA66 (Plastic) / Zinc Alloy Die-cast (Metal)

Solderability: Compliant with IEC 68-2-20

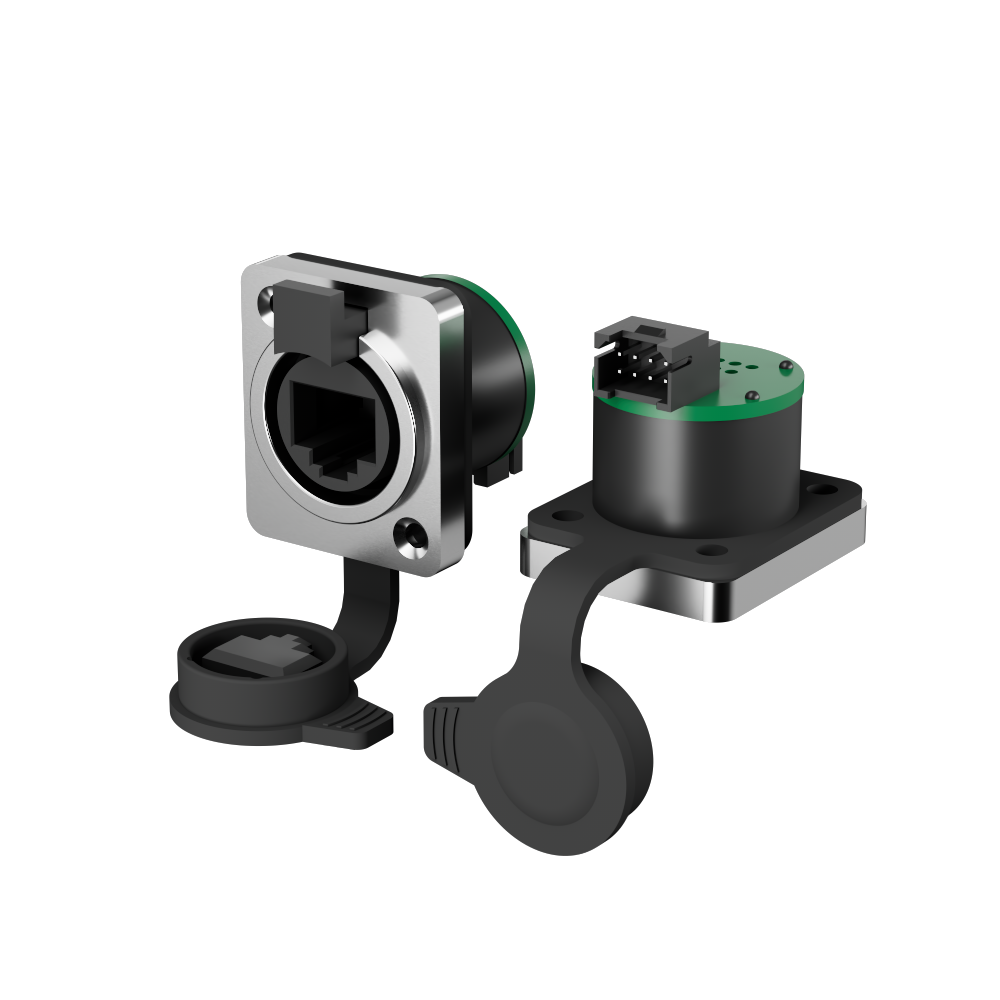

Front Mounting

Key Features

Durable Design: This receptacle features a metal panel with silver and black plating for enhanced durability.

Easy Installation: Designed for front panel mounting with a standard D-cut for seamless integration.

Strong Protection: IP65 rating ensures protection against dust and water ingress.

High Performance: Compliant with Class D specifications, supporting frequencies up to 100MHz, ideal for high-speed data transmission.

Electrical Reliability: With a contact resistance of less than 10 mΩ, a rated current of 1.5 A, and a dielectric strength of 1 kV DC, the receptacle's electrical performance is optimized.

Materials: Constructed from premium materials, including a zinc alloy housing and gold-plated phosphor bronze contacts, ensuring excellent performance and durability over a temperature range of -30°C to +80°C.

Mechanical Parameters:

Insertion Force: ≤60N

Service Life: Over 1000 mating cycles

Locking Device: Latch for secure connection

Assembly Instructions:

During installation, place the waterproof cover gasket on the back of the socket and install it onto the front of the panel. Tighten the screws to a torque of 0.5 Nm to secure the socket. (The panel thickness should be between 1.5 mm and 4 mm.)

5. Foundation of Quality: Thirteen Rigorous Reliability Verifications

We believe that reliability cannot be based solely on promises. Every VOOHU XLR network port must undergo a complete testing process covering four dimensions: electrical, mechanical, environmental, and process. This is the foundation for the long-term stable operation of the product:

Electrical Performance Verification:

Contact Resistance:

a. Use a clamping fixture to hold terminals A and B of the sample under test.

Select the 50mΩ range according to the product.

Apply a maximum voltage of 20mV and a maximum current of 100mA to the assembled terminals for testing.

Judgment Criterion: Contact resistance ≤ 50mΩ

Insulation Resistance:

a. Set test conditions: DC 500V/500MΩ, voltage 220V, normal frequency should be 50 or 60 Hz, time 1 minute.

b. Connect the test object to the test power cord and test fixture, press the TEST button to start the test.

Judgment Criteria: Insulation resistance ≥ 500MΩ

Withstand Voltage Test: Between terminals, AC ≥ 500V, current 0.5mA, time 60s, no breakdown or arcing; Between terminals and housing, AC ≥ 1000V, current 0.5mA, time 60s, no breakdown or arcing;

Mechanical Strength Verification:

Insertion/Extraction Force: Continuously insert and extract the plug at an average speed of 50mm/1min, requiring at least 5 tests (special requirements to be performed as per specifications). Insertion/Extraction Force: 3-20N

Retention Force: The base clip is fixed to the jaws, pulled at a speed of 12.5mm/min. Each sample is pulled 5 times. Holding force ≥12KG, buckle will not break.

Self-locking/unlocking force: Using a male tool with an outer diameter of 18.92mm and an inner diameter of 16.40mm (∅), and an outer diameter of 18.63mm and an inner diameter of -16.40mm (∅ for the small end), insert the large and small ends of the sample together. After insertion, self-locking is achieved (it cannot be pulled open by force in the opposite direction). It can be easily unlocked by pressing the handle with the thumb.

Each sample undergoes 5 self-locking/unlocking cycles.

The self-locking/unlocking function should function normally, without any jamming, inability to unlock, or other defects.

Insertion/removal life test:

a. Insertion/removal speed 150mm-200mm/min.

This standard uses continuous insertion/removal, requiring at least 750 cycles.

Judgment criteria:

a. After the test, the product should not have skipped pins, pin dents, or severe gold layer peeling or scratches.

b. Insertion and extraction force: 3-25N.

c. After durability testing, the change in contact resistance should not exceed 100mΩ, and the insulation resistance should be ≥500MΩ.

e. During withstand voltage testing, no flashing (surface discharge), sparking (air discharge), damage (through-hole discharge), or leakage should occur.

Environmental Tolerance Verification:

High and Low Temperature Tests:

1. Low Temperature Test: Temperature: -40±3℃, maintained for 96 hours under standard conditions, followed by a 30-minute recovery period.

① Appearance: No deformation or loosening.

② Insulation Resistance ≥ 500MΩ

③ Withstand Voltage: AC500V, 1 minute, no breakdown or arcing.

④ Insertion/Extraction Force: 3-25N

⑤ Contact Resistance ≥ 50mΩ

⑥ Terminal Strength: Force 1kg, 10 seconds, no obvious deformation or damage.

2. High Temperature Test: Temperature: 85±2℃, maintained for 96 hours, relative humidity: 90%~95%, under standard conditions, followed by a 30-minute recovery period.

① Appearance: Surface deformation, blistering, discoloration, and peeling are not permitted.

② Insulation resistance ≥ 500MΩ

③ Withstand voltage: AC500V, 1min, no breakdown, no arcing

④ Contact resistance ≥ 50mΩ

⑤ Insertion/extraction force: 3-25N, no deformation or damage to appearance.

⑥ Terminal strength: 1kg force, 10s, no obvious deformation or damage to appearance.

Constant temperature and humidity: Temperature: 40±2℃, Relative humidity: 90%~95%, Time: 96h. Tested under standard conditions, with a 30min recovery period after the test.

① Appearance: No deformation or loosening

② Insulation resistance ≥ 500MΩ

③ Withstand voltage: AC500V, no breakdown or arcing in 1 minute

④ Insertion/extraction force: 3-25N

⑤ Contact resistance ≥ 50mΩ

⑥ Terminal strength: 1kg force, 10s. No obvious deformation or damage.

Salt spray corrosion (48 hours): Samples are placed in an environment with a temperature of 35±5℃, a NaCl concentration of 5%±2%, and continuous spraying for 24-48 hours; iron materials for 8 hours.

① Appearance: No yellowing, discoloration, corrosion, or oxidation.

② Insertion/extraction force: 3-20N

Soldering heat resistance: Simulated wave soldering: Temperature: 240±5℃; Time: 420s;

① Surface deformation, blistering, discoloration, and peeling are not allowed.

② Insulation resistance ≥500MΩ

③ Withstand voltage: AC500V, 1min no breakdown, no arcing

④ Contact resistance ≥50mΩ

⑤ Insertion/extraction force: 3-20N

Process reliability verification:

Solderability test: Solder adhesion: The top of the terminal is immersed in the solder pool to a depth of 2mm, temperature 245±5℃, time 3±0.5 seconds.

Solder adhesion area on the contact surface ≥95%

6. Typical Application Scenarios

Professional Audio Systems: Digital mixing consoles, audio network switches, power amplifiers.

Stage Lighting Control: DMX over Ethernet network nodes, lighting controllers.

Video Transmission and Broadcasting: Video matrices, KVM over IP, OB van systems.

Conference and Control Centers: High-standard fixed installations in enterprises, educational institutions, and public buildings.

VOOHU's Value Promise – Choose VOOHU, Truly Reliable

VOOHU's systematic solutions go beyond just material matching; we empower our clients with three key values:

1. Customized Services: Based on specific client needs, we provide customized hardware design and manufacturing services. Whether it's a special application scenario or personalized functional requirements, we can meet them.

2. One-Stop Procurement: Clients can purchase all the hardware products they need from us, including RJ45 connectors, network transformers, ESD protection devices, and Ethernet port PHYs. One-stop procurement is not only convenient and fast but also reduces costs.

3. Technical Support: We provide comprehensive technical support, from hardware selection to circuit design, from testing and verification to manufacturing. Our technical support team consists of experienced engineers who can quickly respond to client needs and solve their problems.

From its establishment in 2018 to its overseas expansion in 2025, VOOHU Electronics has become a reliable partner for over 1000 companies thanks to its "superior quality, reasonable prices, attentive service, and reliable delivery."

If you're also looking for a reliable, cost-effective, and hassle-free supplier of communication electronic components, consider VOOHU. After all, with over 100 listed companies as a partner, you can't go wrong.

Choosing VOOHU is truly reliable—it's not just a slogan, but the answer written with the trust of over 1000 customers over 8 years.

To address this, VOOHU has launched the XLR-style RJ45 panel mount socket (also known as the XLR A-series) designed specifically for high-standard applications. It innovatively integrates the classic XLR connector locking concept with the RJ45 network interface, aiming to provide a more robust, reliable, and professional physical layer solution for professional audiovisual and lighting networks.

1. Why are XLR RJ45 connectors needed?

In mobile performances, fixed installations, and high-interference environments, connectors must possess the following characteristics:

Vibration and anti-dislodgement: Mechanical latches ensure a secure plug lock, preventing signal interruption due to cable pulling or equipment movement.

High-efficiency shielding: The metal housing version effectively resists external electromagnetic interference, ensuring pure data signals.

Professional appearance and durability: Adaptable to professional equipment panels, durable, and enhancing the overall system quality.

The VOOHU XLR Ethernet series is designed to solve these core pain points.

2. Two Options, Fully Adaptable

To meet the needs of different scenarios, we offer two material options:

All-plastic version: Economical and lightweight, cost-effective, suitable for internal rack interconnection and environments with low electromagnetic shielding requirements.

Metal panel version: Featuring a zinc alloy die-cast housing, it offers superior electromagnetic shielding (EMI/RFI) performance and a more industrial look, making it the preferred choice for demanding projects and high-end equipment.

3. Core Design: Stable Installation, Convenient Locking

Flexible Installation: Supports both vertical and horizontal PCB mounting orientations (90°/180° pins), perfectly adapting to different chassis internal layouts. Designed specifically for industry-standard panel openings.

Reliable Locking: The socket features a built-in stainless steel mechanical latch, forming a secure connection when mated with the matching XLR RJ45 male connector. Easy unlocking is achieved by pressing the "PUSH" button; operation is intuitive.

Wide Compatibility: Compatible with panel thicknesses up to 3mm, offering front/rear mounting options. Securely fastened with M3 screws for stable and convenient installation.

4. Detailed Technical Specifications

Rear Mounting

Electrical Performance

Contact Resistance: < 50mΩ

Insulation Resistance: > 0.5GΩ

Insulation Strength: 1kV DC

Transmission Performance: Fully compliant with CAT5e / Class D standards, supports TIA/EIA 568C and ISO/IEC 11801 channel specifications.

Power Support: PoE++ compatible (IEEE 802.3bt Type 4), maximum power handling 100W.

Important Note: Designed for CAT5e systems; do not use with CAT6/6A connectors.

Mechanical Properties and Environment

Insertion/Extraction Force: ≤ 20N

Insertion/Extraction Life: > 1000 cycles

Operating Temperature: -30°C to +80°C

Protection Rating: IP65 (Dustproof, Waterproof)

Flame Retardant Rating: UL94 V-0

Materials and Processes

Contacts: Phosphor Bronze, Gold Plated (1μ″)

Latch: Stainless Steel

Housing: PA66 (Plastic) / Zinc Alloy Die-cast (Metal)

Solderability: Compliant with IEC 68-2-20

Front Mounting

Key Features

Durable Design: This receptacle features a metal panel with silver and black plating for enhanced durability.

Easy Installation: Designed for front panel mounting with a standard D-cut for seamless integration.

Strong Protection: IP65 rating ensures protection against dust and water ingress.

High Performance: Compliant with Class D specifications, supporting frequencies up to 100MHz, ideal for high-speed data transmission.

Electrical Reliability: With a contact resistance of less than 10 mΩ, a rated current of 1.5 A, and a dielectric strength of 1 kV DC, the receptacle's electrical performance is optimized.

Materials: Constructed from premium materials, including a zinc alloy housing and gold-plated phosphor bronze contacts, ensuring excellent performance and durability over a temperature range of -30°C to +80°C.

Mechanical Parameters:

Insertion Force: ≤60N

Service Life: Over 1000 mating cycles

Locking Device: Latch for secure connection

Assembly Instructions:

During installation, place the waterproof cover gasket on the back of the socket and install it onto the front of the panel. Tighten the screws to a torque of 0.5 Nm to secure the socket. (The panel thickness should be between 1.5 mm and 4 mm.)

5. Foundation of Quality: Thirteen Rigorous Reliability Verifications

We believe that reliability cannot be based solely on promises. Every VOOHU XLR network port must undergo a complete testing process covering four dimensions: electrical, mechanical, environmental, and process. This is the foundation for the long-term stable operation of the product:

Electrical Performance Verification:

Contact Resistance:

a. Use a clamping fixture to hold terminals A and B of the sample under test.

Select the 50mΩ range according to the product.

Apply a maximum voltage of 20mV and a maximum current of 100mA to the assembled terminals for testing.

Judgment Criterion: Contact resistance ≤ 50mΩ

Insulation Resistance:

a. Set test conditions: DC 500V/500MΩ, voltage 220V, normal frequency should be 50 or 60 Hz, time 1 minute.

b. Connect the test object to the test power cord and test fixture, press the TEST button to start the test.

Judgment Criteria: Insulation resistance ≥ 500MΩ

Withstand Voltage Test: Between terminals, AC ≥ 500V, current 0.5mA, time 60s, no breakdown or arcing; Between terminals and housing, AC ≥ 1000V, current 0.5mA, time 60s, no breakdown or arcing;

Mechanical Strength Verification:

Insertion/Extraction Force: Continuously insert and extract the plug at an average speed of 50mm/1min, requiring at least 5 tests (special requirements to be performed as per specifications). Insertion/Extraction Force: 3-20N

Retention Force: The base clip is fixed to the jaws, pulled at a speed of 12.5mm/min. Each sample is pulled 5 times. Holding force ≥12KG, buckle will not break.

Self-locking/unlocking force: Using a male tool with an outer diameter of 18.92mm and an inner diameter of 16.40mm (∅), and an outer diameter of 18.63mm and an inner diameter of -16.40mm (∅ for the small end), insert the large and small ends of the sample together. After insertion, self-locking is achieved (it cannot be pulled open by force in the opposite direction). It can be easily unlocked by pressing the handle with the thumb.

Each sample undergoes 5 self-locking/unlocking cycles.

The self-locking/unlocking function should function normally, without any jamming, inability to unlock, or other defects.

Insertion/removal life test:

a. Insertion/removal speed 150mm-200mm/min.

This standard uses continuous insertion/removal, requiring at least 750 cycles.

Judgment criteria:

a. After the test, the product should not have skipped pins, pin dents, or severe gold layer peeling or scratches.

b. Insertion and extraction force: 3-25N.

c. After durability testing, the change in contact resistance should not exceed 100mΩ, and the insulation resistance should be ≥500MΩ.

e. During withstand voltage testing, no flashing (surface discharge), sparking (air discharge), damage (through-hole discharge), or leakage should occur.

Environmental Tolerance Verification:

High and Low Temperature Tests:

1. Low Temperature Test: Temperature: -40±3℃, maintained for 96 hours under standard conditions, followed by a 30-minute recovery period.

① Appearance: No deformation or loosening.

② Insulation Resistance ≥ 500MΩ

③ Withstand Voltage: AC500V, 1 minute, no breakdown or arcing.

④ Insertion/Extraction Force: 3-25N

⑤ Contact Resistance ≥ 50mΩ

⑥ Terminal Strength: Force 1kg, 10 seconds, no obvious deformation or damage.

2. High Temperature Test: Temperature: 85±2℃, maintained for 96 hours, relative humidity: 90%~95%, under standard conditions, followed by a 30-minute recovery period.

① Appearance: Surface deformation, blistering, discoloration, and peeling are not permitted.

② Insulation resistance ≥ 500MΩ

③ Withstand voltage: AC500V, 1min, no breakdown, no arcing

④ Contact resistance ≥ 50mΩ

⑤ Insertion/extraction force: 3-25N, no deformation or damage to appearance.

⑥ Terminal strength: 1kg force, 10s, no obvious deformation or damage to appearance.

Constant temperature and humidity: Temperature: 40±2℃, Relative humidity: 90%~95%, Time: 96h. Tested under standard conditions, with a 30min recovery period after the test.

① Appearance: No deformation or loosening

② Insulation resistance ≥ 500MΩ

③ Withstand voltage: AC500V, no breakdown or arcing in 1 minute

④ Insertion/extraction force: 3-25N

⑤ Contact resistance ≥ 50mΩ

⑥ Terminal strength: 1kg force, 10s. No obvious deformation or damage.

Salt spray corrosion (48 hours): Samples are placed in an environment with a temperature of 35±5℃, a NaCl concentration of 5%±2%, and continuous spraying for 24-48 hours; iron materials for 8 hours.

① Appearance: No yellowing, discoloration, corrosion, or oxidation.

② Insertion/extraction force: 3-20N

Soldering heat resistance: Simulated wave soldering: Temperature: 240±5℃; Time: 420s;

① Surface deformation, blistering, discoloration, and peeling are not allowed.

② Insulation resistance ≥500MΩ

③ Withstand voltage: AC500V, 1min no breakdown, no arcing

④ Contact resistance ≥50mΩ

⑤ Insertion/extraction force: 3-20N

Process reliability verification:

Solderability test: Solder adhesion: The top of the terminal is immersed in the solder pool to a depth of 2mm, temperature 245±5℃, time 3±0.5 seconds.

Solder adhesion area on the contact surface ≥95%

6. Typical Application Scenarios

Professional Audio Systems: Digital mixing consoles, audio network switches, power amplifiers.

Stage Lighting Control: DMX over Ethernet network nodes, lighting controllers.

Video Transmission and Broadcasting: Video matrices, KVM over IP, OB van systems.

Conference and Control Centers: High-standard fixed installations in enterprises, educational institutions, and public buildings.

VOOHU's Value Promise – Choose VOOHU, Truly Reliable

VOOHU's systematic solutions go beyond just material matching; we empower our clients with three key values:

1. Customized Services: Based on specific client needs, we provide customized hardware design and manufacturing services. Whether it's a special application scenario or personalized functional requirements, we can meet them.

2. One-Stop Procurement: Clients can purchase all the hardware products they need from us, including RJ45 connectors, network transformers, ESD protection devices, and Ethernet port PHYs. One-stop procurement is not only convenient and fast but also reduces costs.

3. Technical Support: We provide comprehensive technical support, from hardware selection to circuit design, from testing and verification to manufacturing. Our technical support team consists of experienced engineers who can quickly respond to client needs and solve their problems.

From its establishment in 2018 to its overseas expansion in 2025, VOOHU Electronics has become a reliable partner for over 1000 companies thanks to its "superior quality, reasonable prices, attentive service, and reliable delivery."

If you're also looking for a reliable, cost-effective, and hassle-free supplier of communication electronic components, consider VOOHU. After all, with over 100 listed companies as a partner, you can't go wrong.

Choosing VOOHU is truly reliable—it's not just a slogan, but the answer written with the trust of over 1000 customers over 8 years.

share to

Related links

You may also like

Prev article

Next article

Newsletter subscription

Subscribe to our newsletter and stay updated on the latest information of our company and product.

Name

|

Subscribe

I agree that the information that I provide will be used in accordance with the terms of Voohu International Inc. Privacy & Cookies Policy