New high performance servo drive system design

1. Industry background and product positioning

With the advancement of Industry 4.0 and intelligent manufacturing, servo drive systems, as core power components in the fields of robots, automated production lines, new energy vehicles, etc., have an increasing demand for high-precision, anti-interference, and multi-protocol communication.

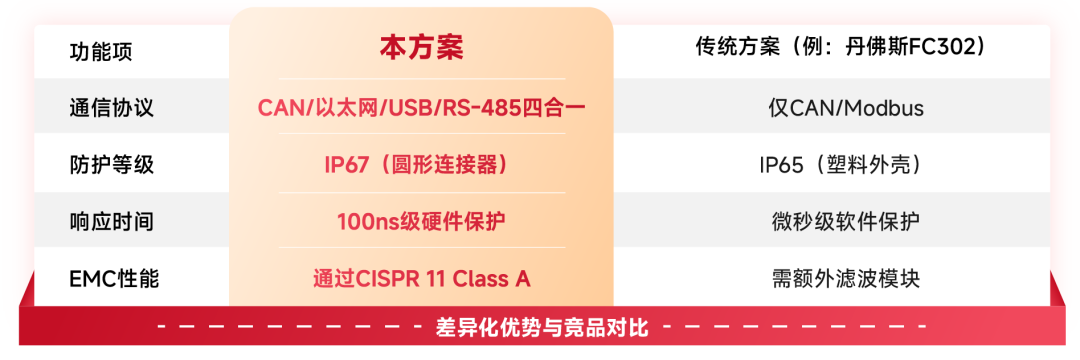

This solution meets the strict industrial-grade scenarios through a unique "3-level protection + 3-core collaboration" architecture (i.e. power protection, signal isolation, EMC optimization + high-performance MCU, multi-protocol communication, and intelligent sensor fusion), directly targeting international brands such as Siemens and Danfoss, and has domestic substitution potential and cost advantages.

2. Analysis of core technologies

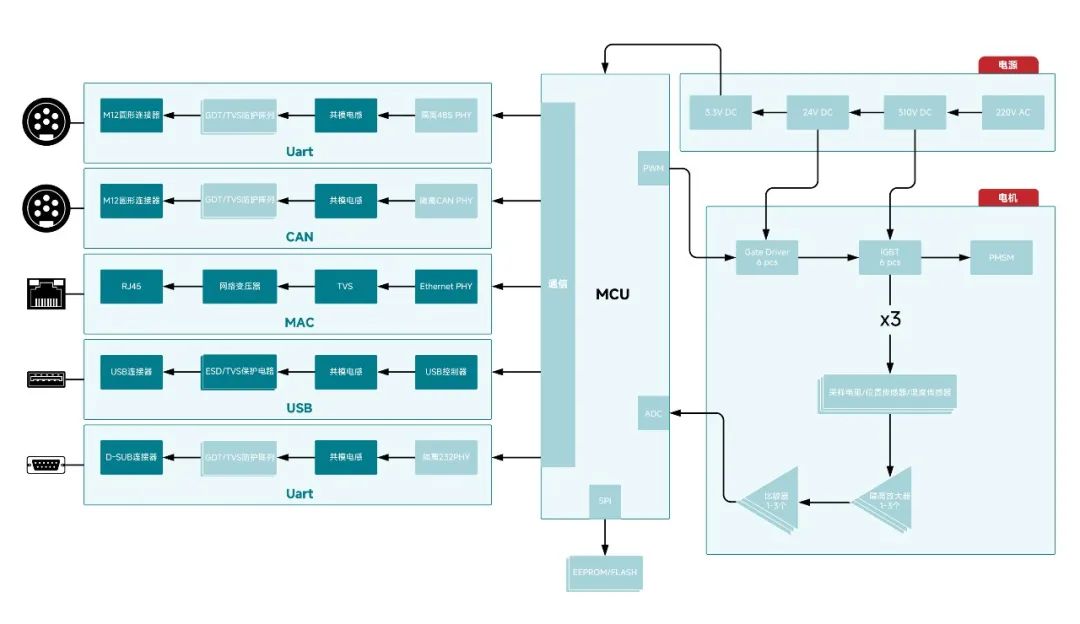

1. Power module: full-link protection and intelligent management

-

High Voltage Rectification and Surge Suppression

-

·The input 220V AC is converted to 310V DC through a three-phase rectifier bridge (Vishay VS-36MT160), and a 3-level protection circuit is deployed at the front end:

·GDT (gas discharge tube): discharges 10kA level lightning surge (IEC 61000-4-5 Level 4).

·TVS (transient suppression diode): clamps the voltage to below 600V (response time ≤1ns).

·Common mode inductor (Würth 744232047): suppresses 150kHz~30MHz conducted noise (insertion loss ≥30dB).

Key indicators

·Bus voltage ripple ≤2%, protection level reaches IEC 61000-4-5 Class 4 (4kV/2kA). -

Isolated power supply design

-

·310V DC is stepped down to 24V through an isolated DC-DC module (RECOM RMD-100-24) for IGBT driving; a low-noise LDO (TI TPS7A47) is used on the secondary side to generate 3.3V to ensure stable operation of the MCU.

Design highlights:

· Inter-stage withstand voltage 3750Vrms (60s) to avoid high and low voltage coupling interference.

· Power efficiency 92%, supporting -40℃~+125℃ wide temperature operation.

2. Motor drive: IGBT intelligent control and protection

-

Full-bridge topology and driver optimization

-

IGBT Selection

-

·Using Infineon FF600R12ME4 (1200V/600A, Vce_sat 1.7V), 6 groups of IGBTs form a three-phase full bridge, supporting 10kHz~20kHz PWM frequency.

Gate Driver Design

· The driver chip STGAP2S integrates the desaturation detection (DESAT) function, and the response time is <100ns.

·Drive current ±4A peak, supports Miller capacitance suppression, and reduces the risk of IGBT false turn-on.

Real-time protection mechanism

·Hardware protection layer: Based on the overcurrent shutdown circuit of the comparator (TI TLV3701), the trigger threshold is dynamically configured through SPI (such as 50A~200A adjustable).

·Software strategy: MCU monitors the phase current (through the isolation amplifier ADI AMC1300) and temperature in real time, and combines the FOC algorithm to achieve multi-level load reduction protection.

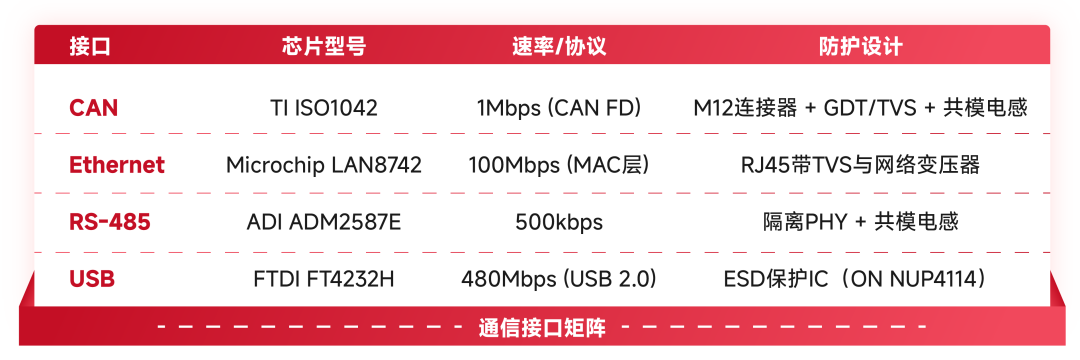

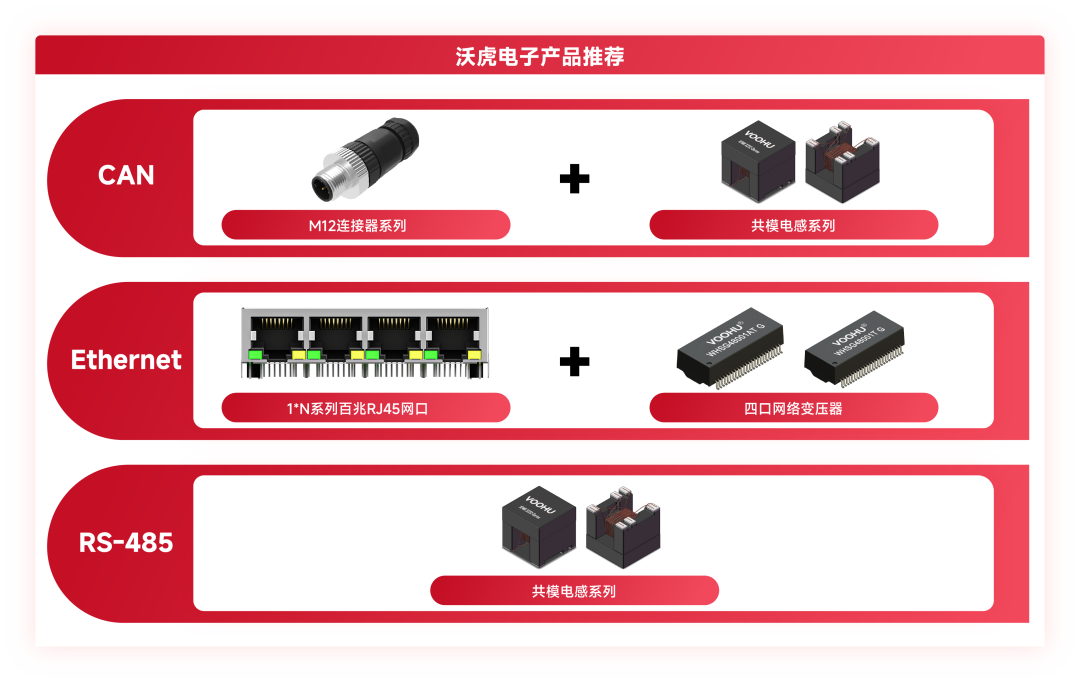

3. Communication and sensing: industrial-grade multi-protocol integration

-

Sensor fusion technology

· Position feedback: Magnetic encoder (AMS AS5048A) is transmitted via SPI differential interface, and the noise resistance is improved by 10 times (error <0.05°).

· Temperature monitoring: PT1000 platinum resistor + constant current source circuit + 24-bit ADC (ADI AD7124), accuracy ±0.1℃.

3. Differentiation and Comparison with Competitive Products

4. Typical Application Scenarios and User Value

1. Industrial robot joint drive

-

Pain point requirements

· High frequency start and stop, position accuracy (±0.01°), vibration environment.

Solution value:

· CAN bus synchronizes multi-joint posture, delay <1ms.

· M12 connector shockproof design, MTBF (mean time between failures) >50,000 hours.

2. AGV logistics vehicle drive system

-

Pain point requirements

·Multi-vehicle collaboration, outdoor anti-interference, and fast maintenance.

Solution value:

·Real-time path data upload via Ethernet, supporting OTA upgrades.

·TVS protection array passes ISO 7637-2 vehicle surge test.

3. High-end CNC machine tool spindle control

-

Pain point requirements

· High-speed cutting (20,000rpm), multi-axis linkage.

Solution value:

· FOC algorithm ultra-low harmonic distortion (THD < 2%).

· Isolation amplifier achieves 0.1% current sampling accuracy.

Newsletter subscription

Subscribe to our newsletter and stay updated on the latest information of our company and product.

Name

|

I agree that the information that I provide will be used in accordance with the terms of Voohu International Inc. Privacy & Cookies Policy

![[Revolutionizing the Future of Industrial IoT] SPE Single Pair Ethernet Technology: An Efficient Communication Revolution from Sensors to the Cloud](/upload/image/20250509/bb391270945a0fd93d2658940a69e578.jpg)