Planar Transformer Technology White Paper

1、FUNCTION INTRODUCTIONE

Definition:

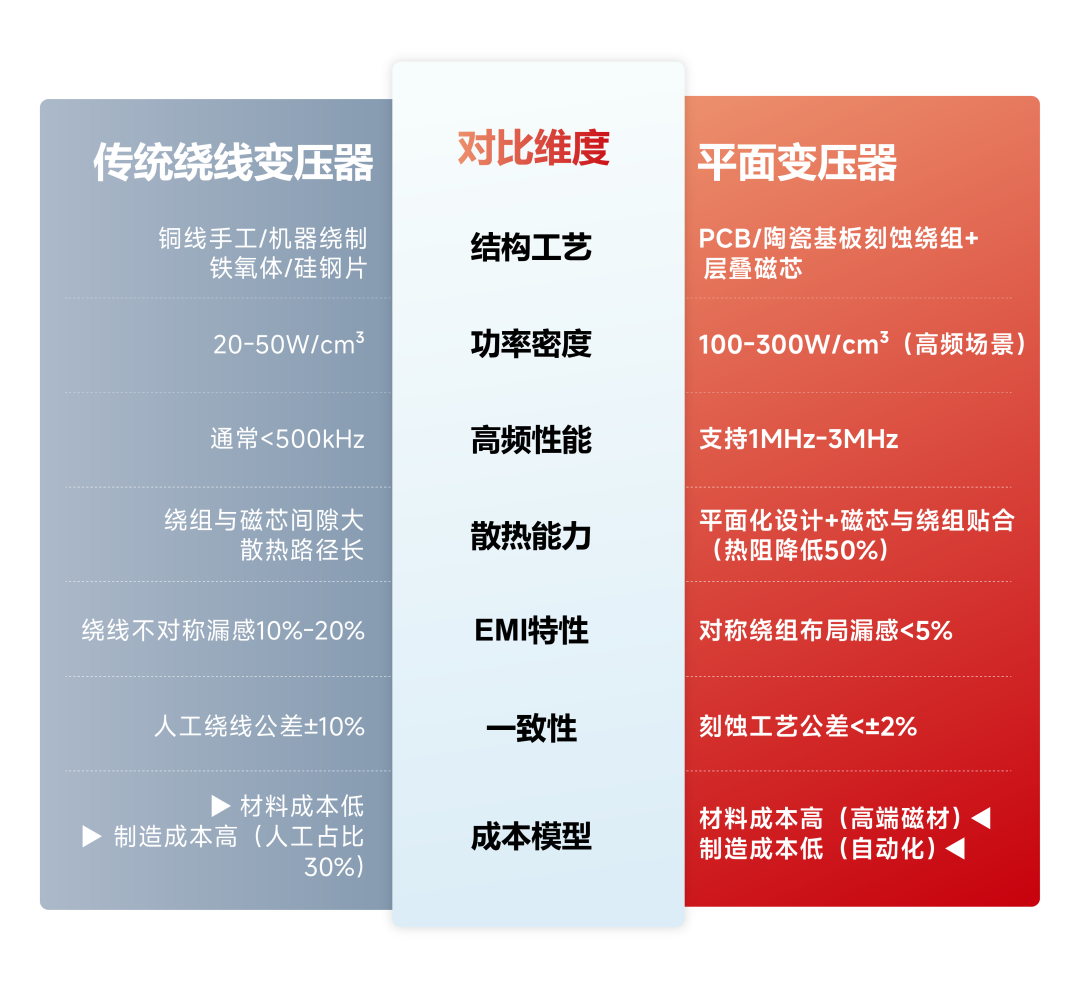

A planar transformer is a high-frequency transformer manufactured with a special structure and process, and works on the principle of electromagnetic induction. Compared with traditional wound transformers, the core and winding of a planar transformer are both planar structures, with the advantages of small size, light weight, and easy integration.

Structure:

1. Magnetic core: usually made of high-frequency power ferrite materials, such as E-type, RM-type, EC, ETD, and EER-type.

2. Winding: The winding is made of a multi-layer printed circuit board (PCB) or folded into a multi-layer coil using copper foil.

3. Insulation material: The windings are insulated with thin insulating sheets (such as Mylar, Nomex, or Kapton).

Function:

Voltage conversion, current conversion, impedance conversion, isolation, voltage regulation;

Structure: Advantages:

• High power density: small size, high power density.

• High efficiency: efficiency can reach more than 98%.

• Low leakage inductance: small leakage inductance, about 0.2% of the primary inductance.

• Good heat dissipation: short heat channel distance and large heat dissipation area.

• Low EMI radiation: good core shielding to reduce electromagnetic interference.

• Easy to integrate: suitable for surface mounting and easy for automated production.

2、MARKET INFORMATION

Five core advantages of planar transformers

Disruptive volume reduction

• Thickness: minimum 3mm (traditional ≥15mm)

• Case: 60% reduction in volume of fast charging adapter

High frequency and high efficiency

• Efficiency still >94% at 2MHz (traditional 90% at 500kHz)

• On-board charger switching frequency increased to 1.2MHz

Extreme environment reliability

• Operating temperature: -55℃~+150℃ (traditional -20℃~+125℃)

• Anti-vibration performance: passed 30G acceleration shock test

System-level cost savings

• Save 30%+ PCB area

• Heat sink volume reduced by 70%

Supply stability guarantee

• Production cycle: 3-5 days (customized traditional transformers take 2-3 weeks)

• No production capacity fluctuations caused by manual winding

Main application areas

1. New energy vehicles

• 800V high-voltage fast charging system

• On-board DC-DC converter

• BMS battery management system

2. Data center/communication power supply

• 48V→12V DC conversion

• PoE++ power supply

• 5G base station RF power supply

3. Consumer electronics

• Gallium nitride fast charging

• AR/VR device power supply

4. Aerospace

• Radiation-resistant design

• 55℃~+200℃ wide temperature range

3、PRODUCT PARAMETERS

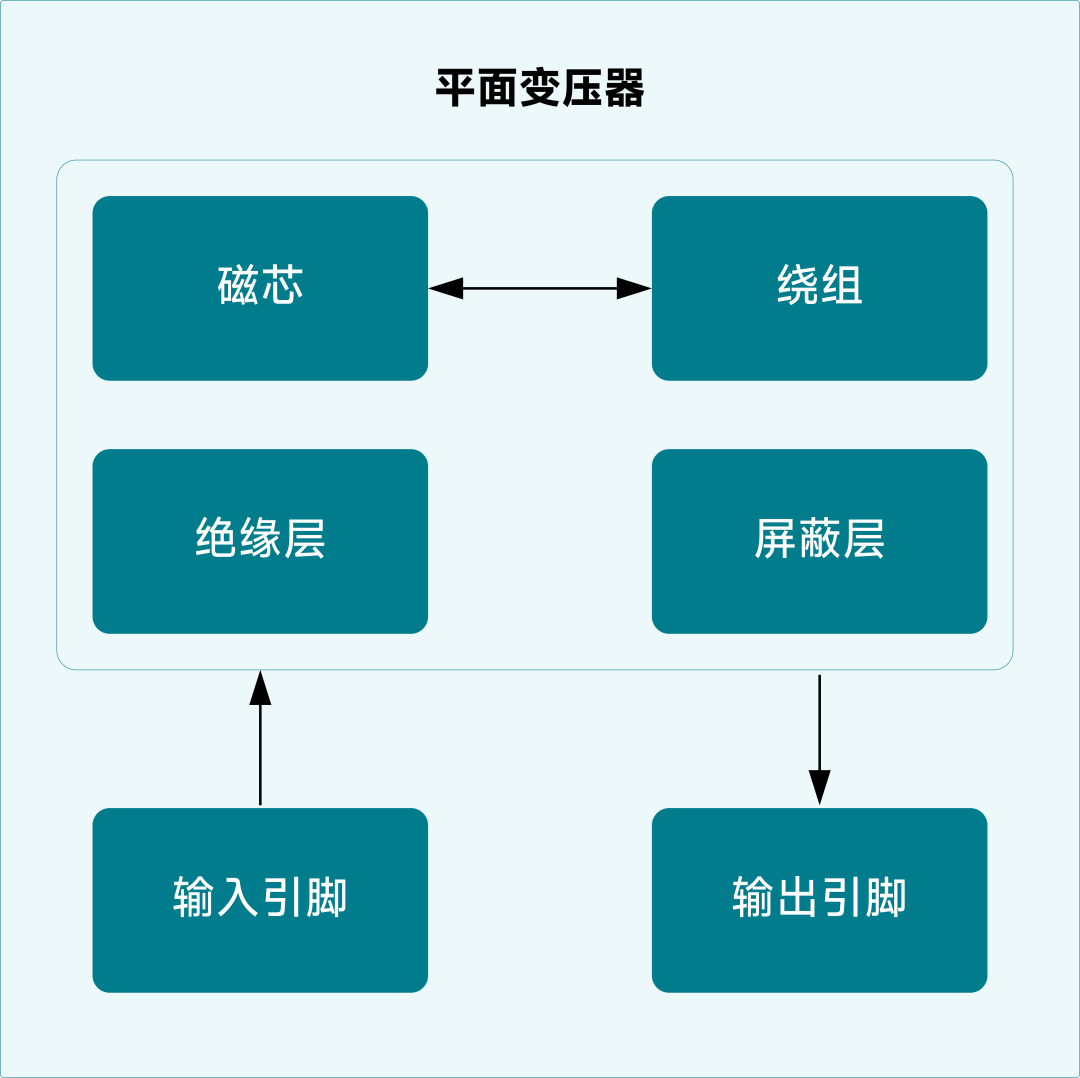

4、PRODUCT FRAMEWORK

1. Magnetic core:

• Function: Provide magnetic circuit to realize electromagnetic induction.

• Material: High-frequency power ferrite materials are usually used, such as E type, RM type, EC, ETD and EER type.

• Function: The magnetic core is the core component of the transformer, responsible for converting the input electrical energy into magnetic energy, and then into output electrical energy.

2. Winding:

• Function: Realize the conversion of voltage and current.

• Structure: The winding is usually made of multi-layer printed circuit boards (PCBs) or folded into multi-layer coils using copper foil.

• Function: The winding is divided into primary winding and secondary winding. The primary winding receives the input voltage and the secondary winding outputs the required voltage.

3. Insulation layer:

• Function: Prevent short circuit and leakage between windings.

• Material: Commonly used insulation materials include Mylar, Nomex or Kapton.

• Function: The insulation layer ensures electrical isolation between windings and improves the safety and reliability of the transformer.

4. Shielding layer:

• Function: Reduce electromagnetic interference and improve electromagnetic compatibility.

• Material: Metal materials such as copper or aluminum are usually used.

• Effect: The shielding layer can effectively reduce the electromagnetic interference of the transformer to the external circuit, and also reduce the impact of external electromagnetic interference on the transformer.

5. Cooling system:

• Function: Ensure that the transformer maintains a proper temperature during operation.

• Structure: The cooling system can include heat sinks, fans or liquid cooling devices.

• Effect: The cooling system helps to improve the efficiency and life of the transformer and prevent failures caused by overheating.

6. Input pins and output pins:

• Function: Connect the transformer to the external circuit.

• Structure: The input pin is connected to the primary winding and the output pin is connected to the secondary winding.

• Effect: The pin is the interface between the transformer and the external circuit to ensure the input and output of electrical energy.

5、APPLICATION FIELDS

1. Consumer electronics:

• Smartphones: used in fast charging power adapters to achieve high power density and miniaturized design.

• Laptops: used in power adapters to improve power conversion efficiency and portability.

• Tablets: used in power management modules to provide efficient and stable power.

• Digital cameras: used in internal power modules to achieve miniaturization and high efficiency.

2. Communication equipment:

• Base stations: used in base station power modules to provide efficient and stable power.

• Routers: used in power modules to achieve efficient power conversion.

• Switches: used in power modules to provide stable power support.

3. Automotive electronics:

• Electric vehicles: used in on-board chargers and DC-DC converters to provide high power density and high efficiency.

• Charging piles: used in power modules for charging piles to achieve fast charging and high efficiency.

4. Medical equipment:

• Medical instruments: used in internal power modules to provide high efficiency and low noise power.

• Portable medical equipment: used in power modules to achieve miniaturization and high efficiency.

5. Industrial Control:

• Industrial Power Supply: Used in power modules to provide high-efficiency and high-reliability power supply.

• Automation Equipment: Used in power modules to achieve high efficiency and miniaturization.

6. Aerospace:

• Avionics Equipment: Used in internal power modules to provide high-efficiency and high-reliability power supply.

• Satellite Communication Equipment: Used in power modules to achieve high efficiency and miniaturization.

7. Renewable Energy:

• Solar Inverter: Used in power conversion modules in inverters to achieve high efficiency and miniaturization.

• Wind Energy System: Used in power conversion modules in frequency converters to provide high efficiency and high reliability.

Newsletter subscription

Subscribe to our newsletter and stay updated on the latest information of our company and product.

Name

|

I agree that the information that I provide will be used in accordance with the terms of Voohu International Inc. Privacy & Cookies Policy