SFP fiber cage standards and corrosion resistance test

SFP fiber cage standards and corrosion resistance test

The reliability of the SFP (Small Form-factor Pluggable) cage, as the mechanical and electrical interface of high-speed optical/electrical modules, directly affects the stability of the system. To verify its performance in harsh environments, the industry standard defines multiple types of extreme tests, mainly covering four dimensions: mechanical reliability, environmental adaptability, electrical robustness, and long-term durability. The following are typical test items and their purposes:

────────────────────────────────────────────────

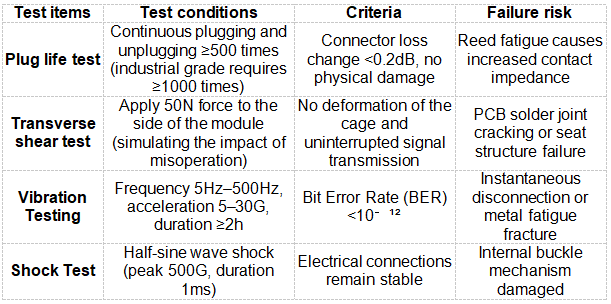

1. Mechanical reliability test (verification of physical structure strength)

**Typical use cases**: In-vehicle equipment must pass **MIL-STD-883** vibration standards, and communication equipment must meet **GR-468-CORE**.

────────────────────────────────────────────────

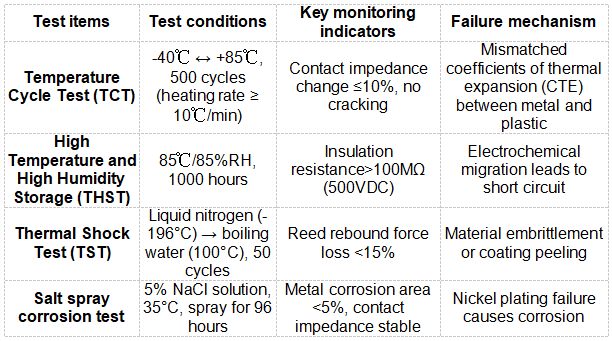

2. Environmental adaptability test (challenging temperature and humidity limits)

**Plating requirements**: The contact area needs to be ≥0.76μm gold plating + nickel base layer (to prevent copper diffusion).

────────────────────────────────────────────────

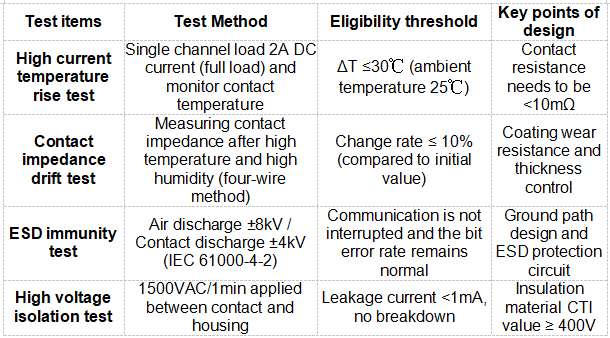

三、Electrical stability testing (signal integrity under extreme conditions)

────────────────────────────────────────────────

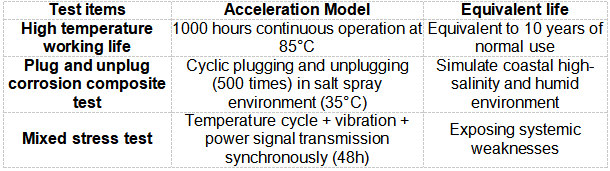

4. Long-term durability test (accelerated life simulation)

────────────────────────────────────────────────

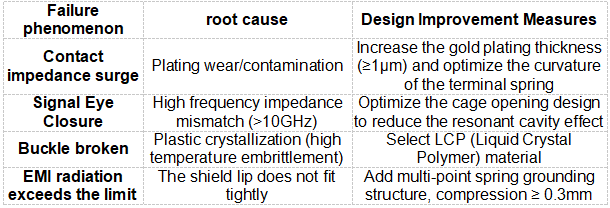

Failure Modes and Design Countermeasures

────────────────────────────────────────────────

Industry testing standard system

- Mechanical and Environmental: IEC 61753 (Fiber Optic Components), Telcordia GR-468-CORE

- Electrical safety: IEC 62368-1 (safety regulations), ANSI/TIA-968-A (connectors)

- EMC: FCC Part 15, EN 55032/55035

- High-speed performance: IEEE 802.3 (Ethernet), SFF-8472 (diagnostics)

────────────────────────────────────────────────

Key points of engineering practice

- Reed material selection: Phosphor bronze (C5191) is better than brass (high elastic modulus, fatigue resistance)

- Key dimension control: PCB installation coplanarity ≤ 0.1mm, ensuring uniform crimping of the shielding shell

- Signal integrity optimization: ground via arrays are placed at the edge of the cage window (to suppress edge radiation)

⚠️ **Note**: SFP+/QSFP cages require additional testing of **25G+/100G+ channel crosstalk**, and isolation >35dB is verified through electromagnetic simulation (such as HFSS).

These tests ensure that the SFP cage can maintain reliable connections for more than 10 years in scenarios such as high temperature and humidity in data centers, severe vibration in vehicles, and industrial dust corrosion. They are the cornerstone of quality control for high-speed interconnection equipment.

Newsletter subscription

Subscribe to our newsletter and stay updated on the latest information of our company and product.

Name

|

I agree that the information that I provide will be used in accordance with the terms of Voohu International Inc. Privacy & Cookies Policy