Voohu Electronics BMS Isolation Communication Transformer---Building a Highly Reliable Communication Bridge for Energy Storage and Automotive Systems

Voohu Electronics BMS Isolation Communication Transformer---Building a Highly Reliable Communication Bridge for Energy Storage and Automotive Systems

1. Industry Challenge: The Noise Dilemma in BMS Communication

In a battery management system (BMS), the stability of the communication link directly determines battery safety and lifespan.

Whether it's the complex electromagnetic environment of electric vehicles (EMI sources such as inverters and relays) or the long links and multiple modules in series in energy storage systems, they all face the following challenges:

▪ High-voltage differential interference (battery packs reach over 1000V)

▪ Common-mode noise causing data distortion

▪ Risk of safety isolation failure

Industry needs: Communication magnetic solutions with high isolation, strong noise immunity, and a wide temperature range.

2. Voohu Electronics Solution: The Core Value of Isolation Communication Transformers

Voohu Electronics, deeply engaged in the research and development of magnetic devices, has launched a series of isolation communication transformers specifically designed for BMS, providing the following for the energy storage and automotive sectors:

▪ Anti-EMI Design: Utilizes a transformer coupling circuit to block common-mode noise transmission, adapting to high-interference scenarios such as automotive inverters and motor drives.

▪ High-Safety Isolation: Supports operating voltages up to 1600VDC, and the 4500VDC insulation withstand voltage meets ISO26262 functional safety requirements.

▪ Wide Operating Temperature Range: -40°C to 125°C, with stable performance across the entire temperature range.

▪ Long-Distance Daisy Chain Support: Multi-channel design (e.g., single/dual channel) ensures reliable communication in cascaded multi-module energy storage systems.

▪ Active Balancing Support: The center tap design is compatible with active balancing circuits, extending battery pack life (saving over 30% energy compared to passive balancing).

▪ Strengthened insulation protection: minimum creepage distance ≥11mm to cope with high humidity and high dust environment of ESS.

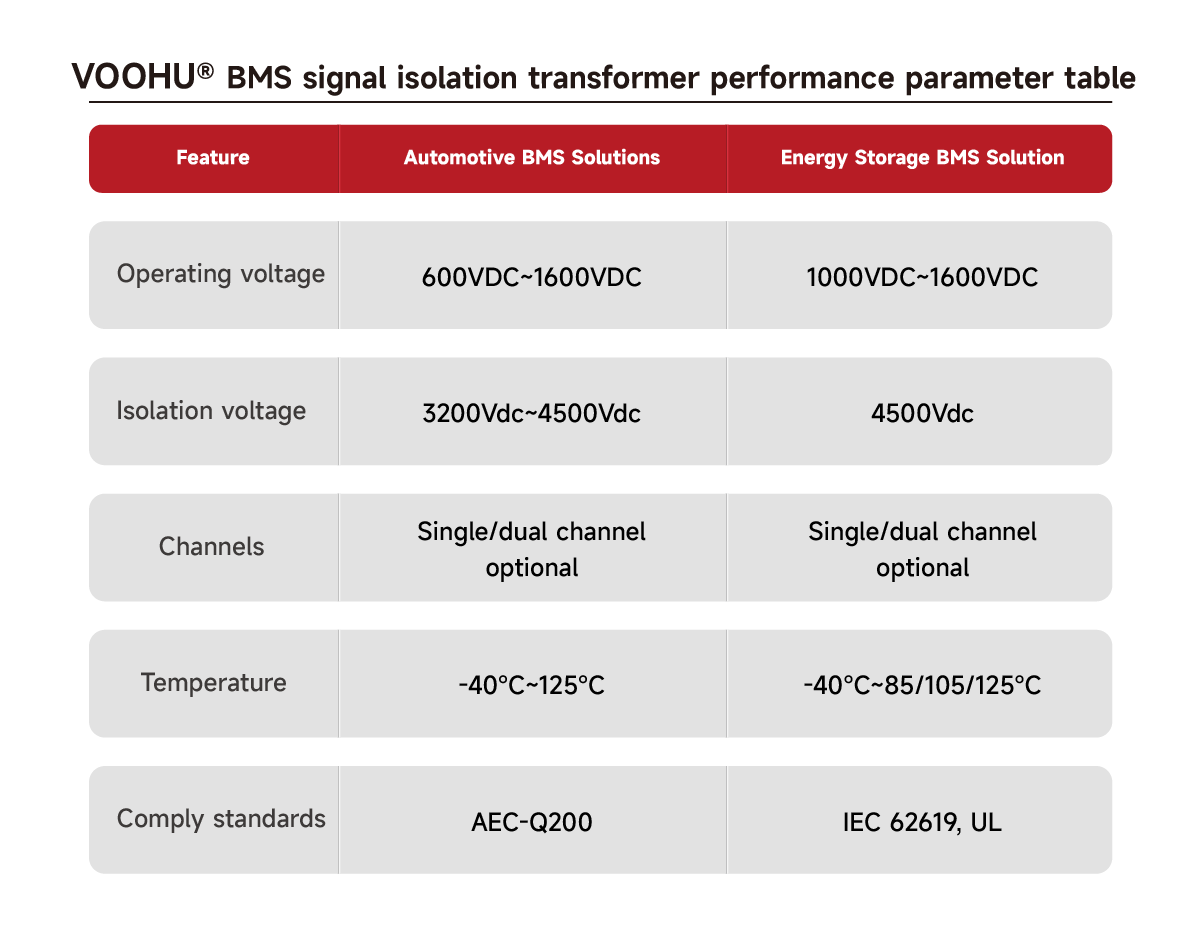

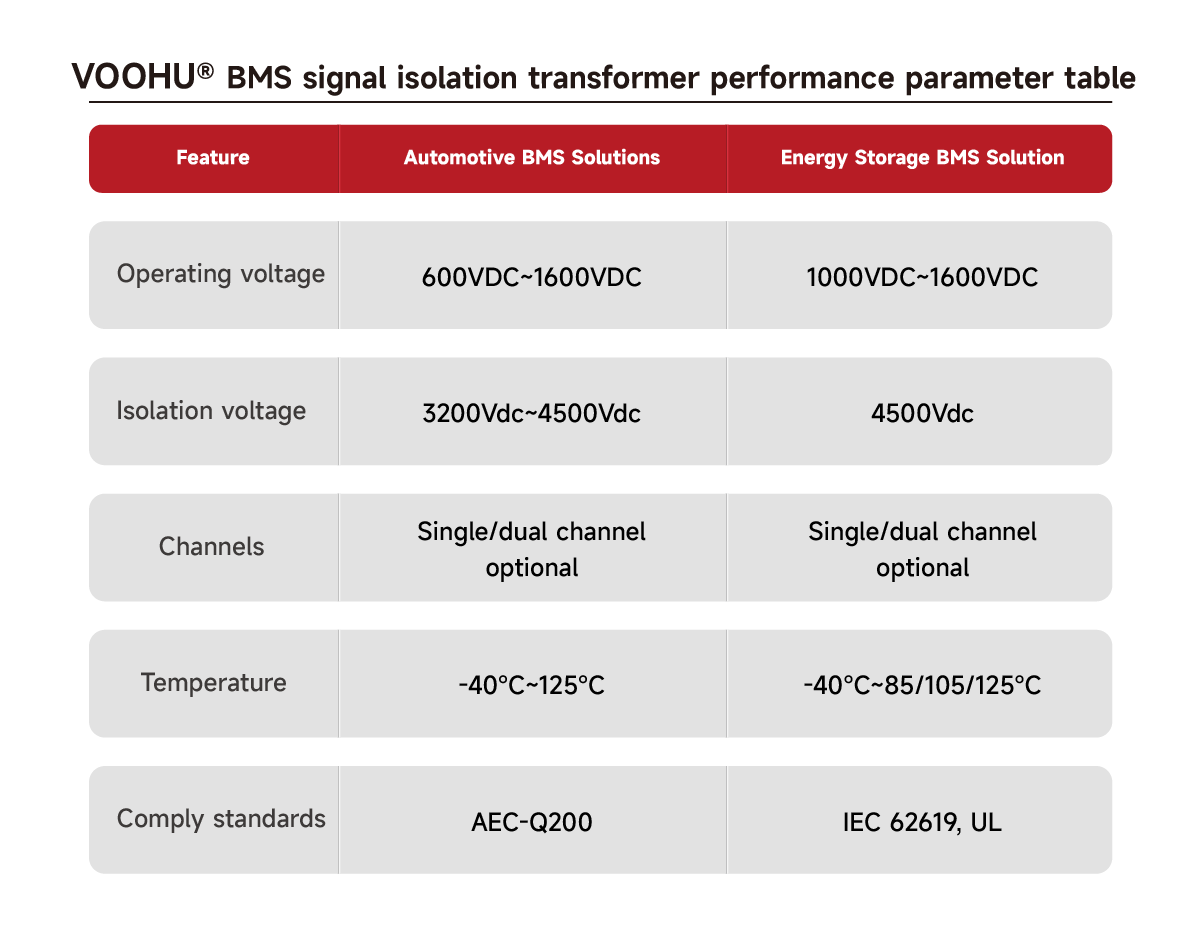

3. Key performance parameters

4. Application Scenario Illustration

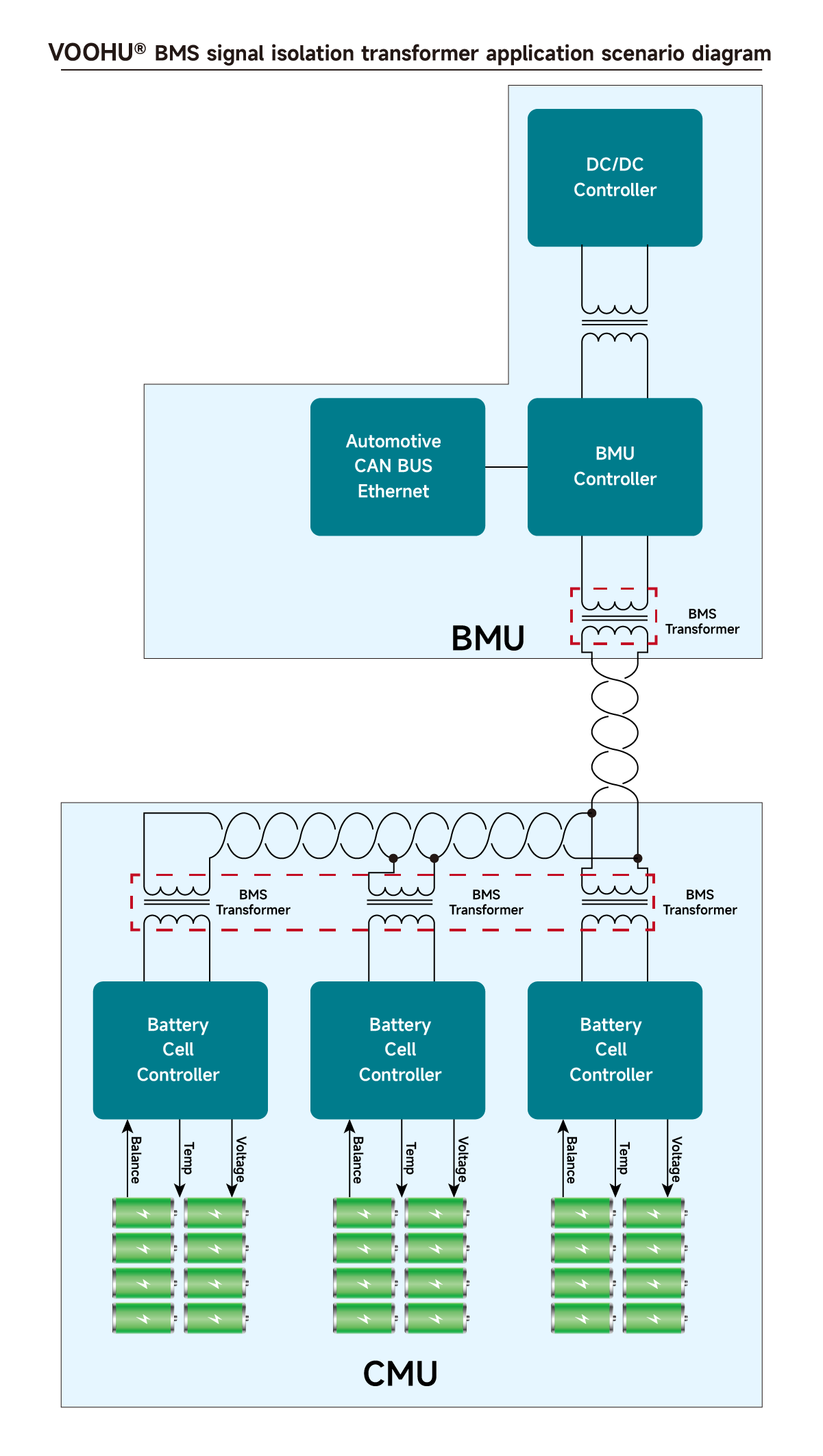

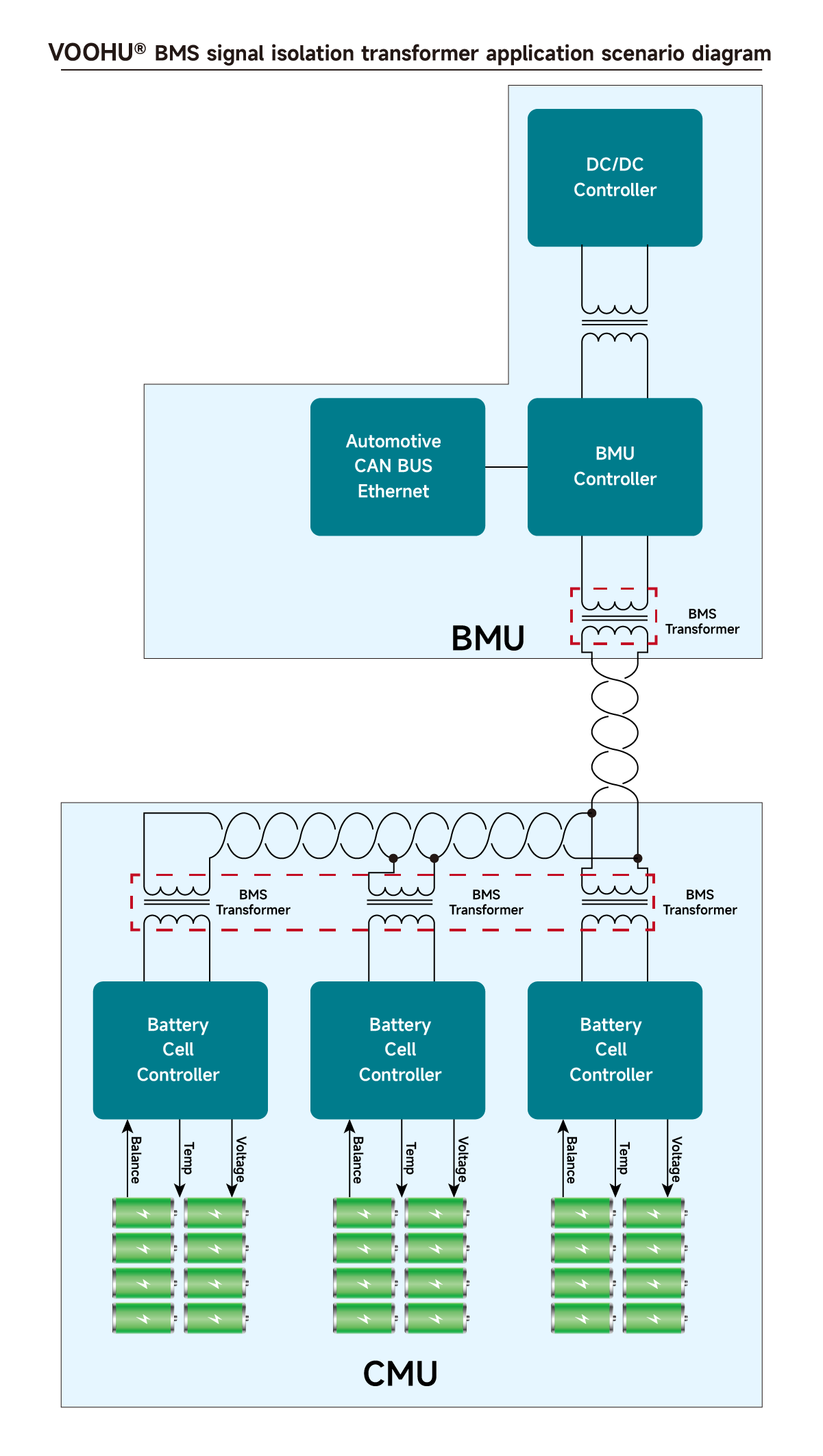

A battery management system measures voltage and stops charging battery cells during charging. Its primary goal is to achieve optimal battery reliability, performance, and lifespan.

The battery management system's electronics need to transmit measurement data to a central processor. Due to the presence of inverters, actuators, solid-state switches, relays, and other electromagnetic interference (EMI) sources in the vehicle, the battery management system operates in an electrically noisy environment. Therefore, the data communication link must be isolated and EMI suppressed to provide adequate noise cancellation.

A battery management system has two main circuits: the battery management controller (BMU) on one side and the cell management controller (CMU) on the other. The CMU divides its functions into two parts: monitoring and cell balancing.

The monitoring application provides "real-time" battery voltage and temperature data, while cell balancing extends the battery's lifespan by charging or discharging battery cells (active cell balancing) and proactively preventing overheating (passive cell balancing).

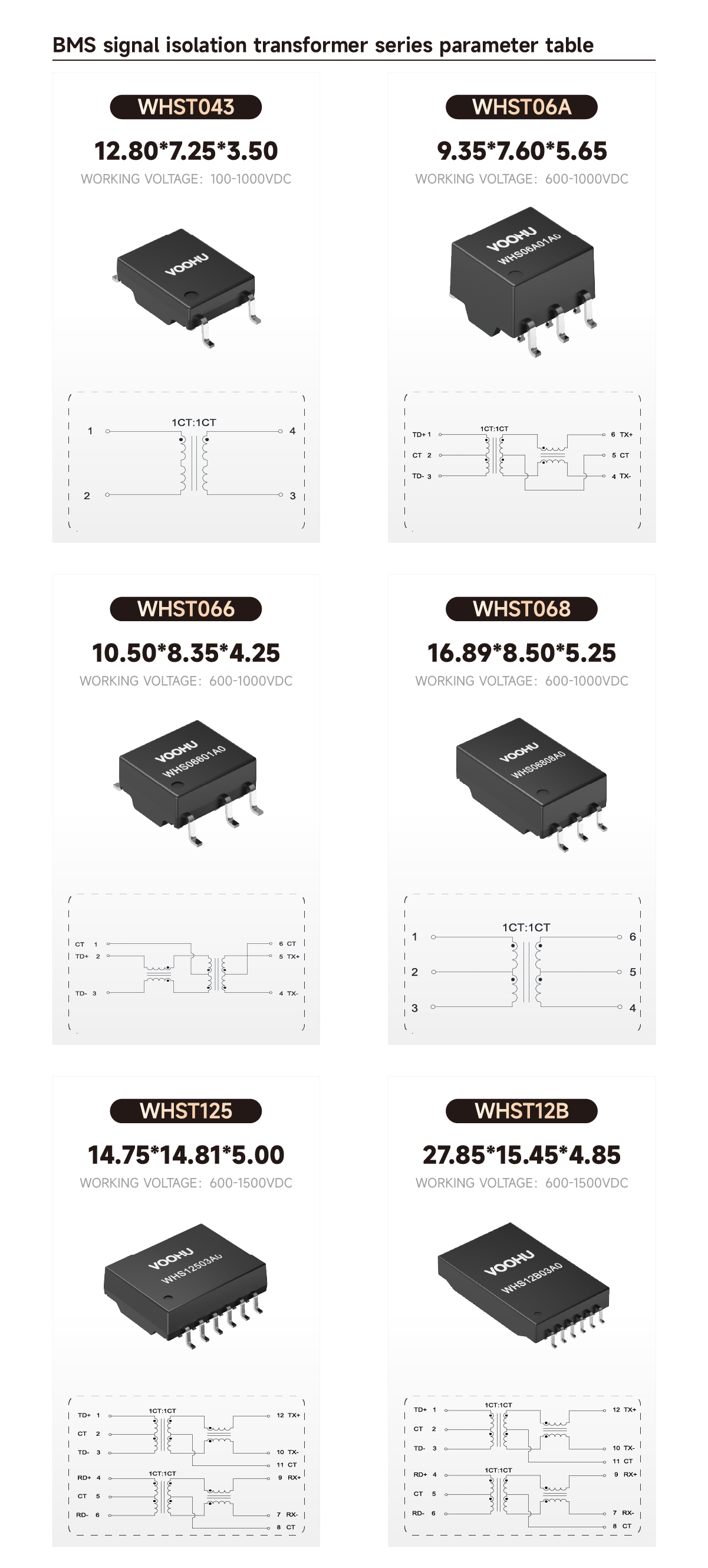

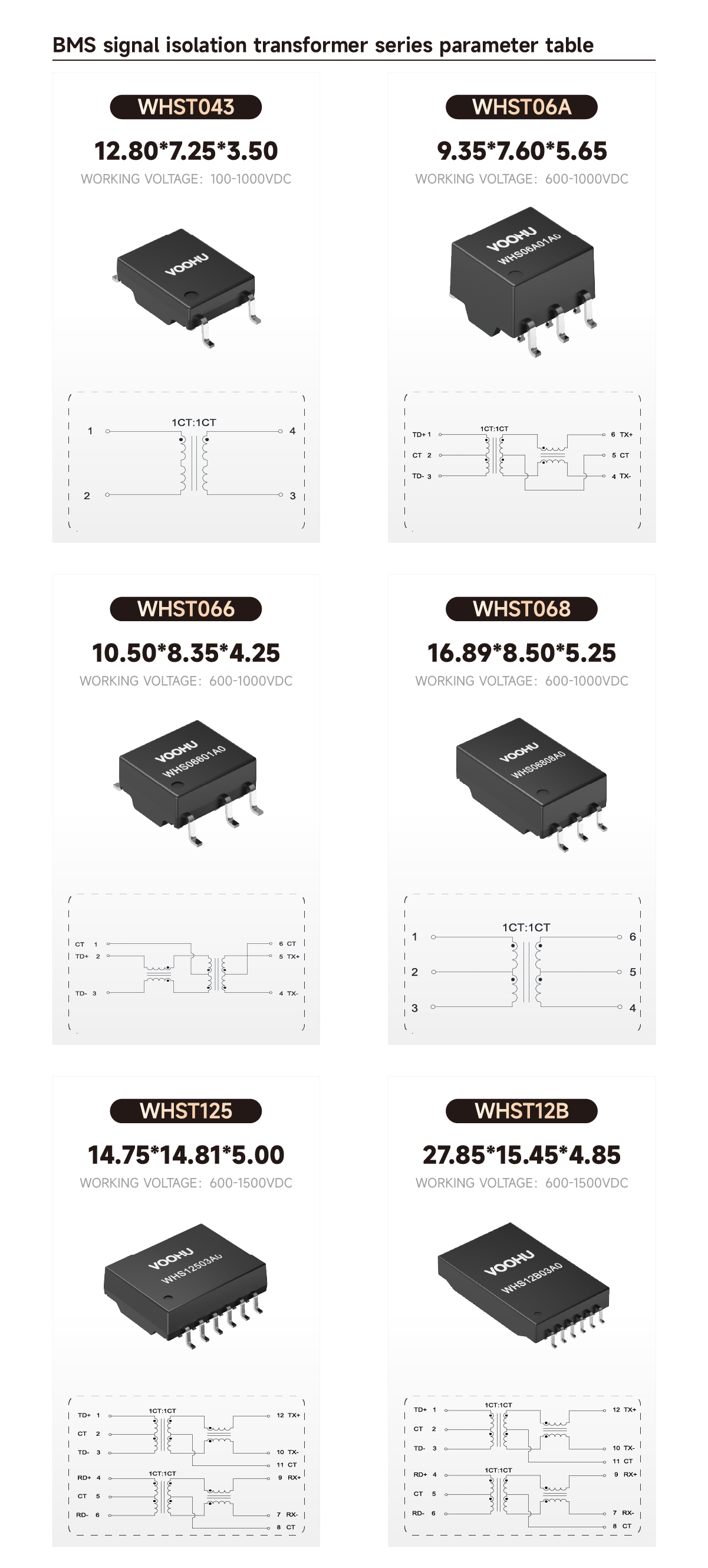

5. Voohu BMS Transformer Product Family

5. Voohu BMS Transformer Product Family

Application scenarios:

In a battery management system (BMS), the stability of the communication link directly determines battery safety and lifespan.

Whether it's the complex electromagnetic environment of electric vehicles (EMI sources such as inverters and relays) or the long links and multiple modules in series in energy storage systems, they all face the following challenges:

▪ High-voltage differential interference (battery packs reach over 1000V)

▪ Common-mode noise causing data distortion

▪ Risk of safety isolation failure

Industry needs: Communication magnetic solutions with high isolation, strong noise immunity, and a wide temperature range.

2. Voohu Electronics Solution: The Core Value of Isolation Communication Transformers

Voohu Electronics, deeply engaged in the research and development of magnetic devices, has launched a series of isolation communication transformers specifically designed for BMS, providing the following for the energy storage and automotive sectors:

▪ Anti-EMI Design: Utilizes a transformer coupling circuit to block common-mode noise transmission, adapting to high-interference scenarios such as automotive inverters and motor drives.

▪ High-Safety Isolation: Supports operating voltages up to 1600VDC, and the 4500VDC insulation withstand voltage meets ISO26262 functional safety requirements.

▪ Wide Operating Temperature Range: -40°C to 125°C, with stable performance across the entire temperature range.

▪ Long-Distance Daisy Chain Support: Multi-channel design (e.g., single/dual channel) ensures reliable communication in cascaded multi-module energy storage systems.

▪ Active Balancing Support: The center tap design is compatible with active balancing circuits, extending battery pack life (saving over 30% energy compared to passive balancing).

▪ Strengthened insulation protection: minimum creepage distance ≥11mm to cope with high humidity and high dust environment of ESS.

3. Key performance parameters

4. Application Scenario Illustration

A battery management system measures voltage and stops charging battery cells during charging. Its primary goal is to achieve optimal battery reliability, performance, and lifespan.

The battery management system's electronics need to transmit measurement data to a central processor. Due to the presence of inverters, actuators, solid-state switches, relays, and other electromagnetic interference (EMI) sources in the vehicle, the battery management system operates in an electrically noisy environment. Therefore, the data communication link must be isolated and EMI suppressed to provide adequate noise cancellation.

A battery management system has two main circuits: the battery management controller (BMU) on one side and the cell management controller (CMU) on the other. The CMU divides its functions into two parts: monitoring and cell balancing.

The monitoring application provides "real-time" battery voltage and temperature data, while cell balancing extends the battery's lifespan by charging or discharging battery cells (active cell balancing) and proactively preventing overheating (passive cell balancing).

5. Voohu BMS Transformer Product Family

5. Voohu BMS Transformer Product Family

Application scenarios:

share to

Related links

01 Core technical specifications and risk prevention and control guidelines for network transformer wiring

03 Troubleshooting Guide for Ethernet Communication Anomalies: In-depth Analysis of PHY and Network Transformer Selection and Wiring Design Issues

You may also like

Prev article

Next article

Newsletter subscription

Subscribe to our newsletter and stay updated on the latest information of our company and product.

Name

|

Subscribe

I agree that the information that I provide will be used in accordance with the terms of Voohu International Inc. Privacy & Cookies Policy